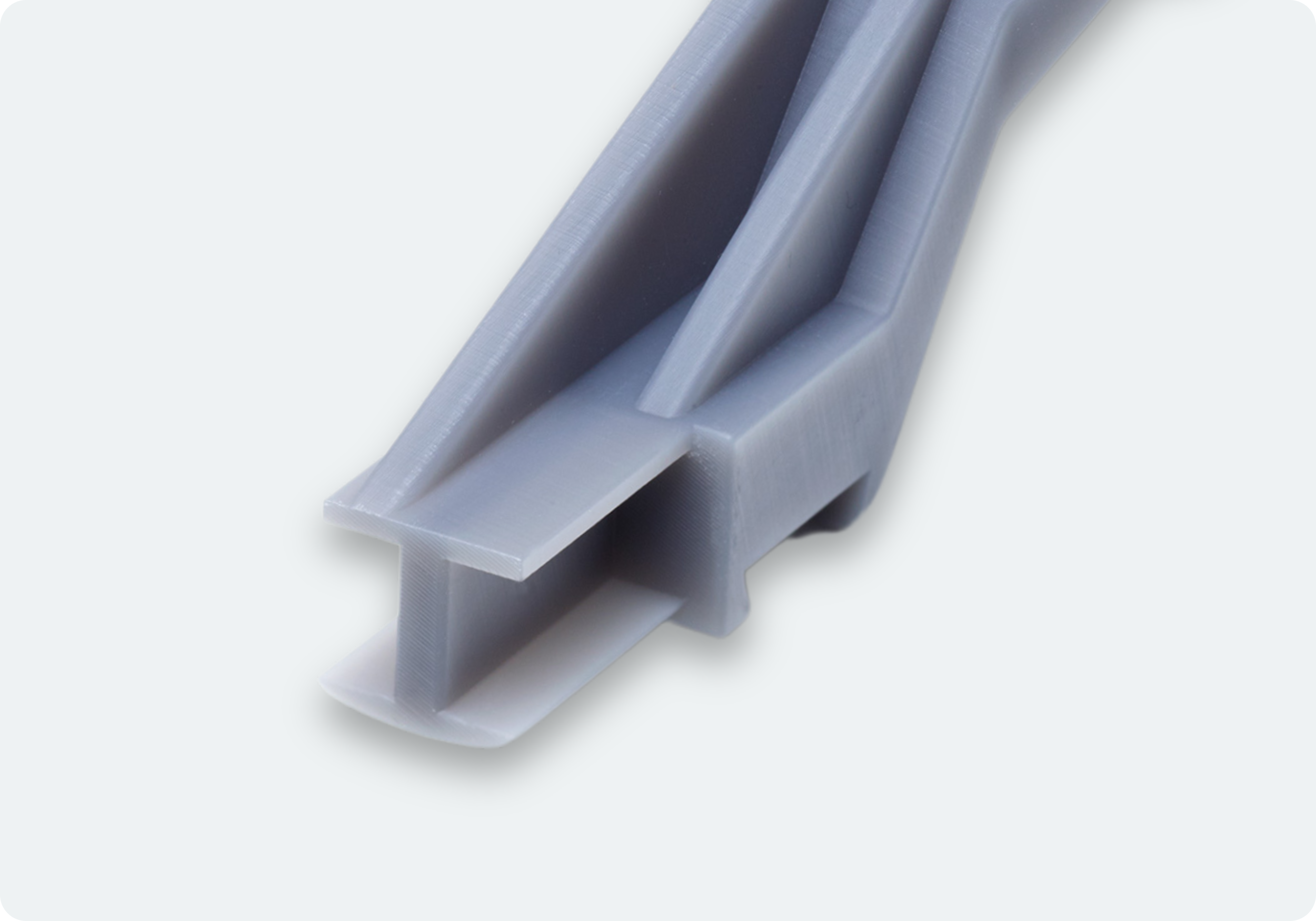

Stereo Lithography Appearance

High-quality surfaces. Laser-sharp precision. Obtain optical prototypes and detailed components in the shortest possible time with the help of “Stereo Lithography Appearance (SLA)”.

What is Stereo Lithography Appearance?

Stereo Lithography Appearance involves printing from a synthetic resin, known as resin. Similar to SLS printing, this is hardened at the relevant points with the help of a laser. This produces components with extreme attention to detail and high-quality surfaces. SLA printing is therefore perfect for optical prototyping and high-performance components.

Our SLA printing capacities

Maximum size

145 x 145 x 175 mm (L x W x H)

Standard production time

3 working days

Dimensional accuracy

± 0.5% with a lower limit of ± 0.15mm

Layer thickness

50 - 100 µm

Upload your CAD files now and calculate your SLA print in real time!

Materials for SLA printing

Standard White

Very detailed, matt surfaces and high resolution of up to 25 micrometers, no special material properties.

Heat resistant up to approx. 60°CGPro

Moderate elongation, low creep behavior. Excellent suitability for modeling concepts and functional prototypes.

Heat resistant up to approx. 65°CRigid 10k

Glass-filled resin with extreme rigidity. Withstands very high loads without bending. Highly resistant to heat and chemicals.

Heat resistant up to approx. 150°C.png?width=2000&height=1400&name=Website%20SLA-Nachbearbeitung%20(1).png)

SLA-printed components of the highest quality

For SLA-printed components, we take most of the time for post-processing. After washing and hardening the components, we don't just remove the supports. Each component is re-filed and sometimes even sandblasted so that you receive your components with the best possible surface quality.