Selective laser sintering

Procure high-quality end products as well as robust and functional prototypes using the 3D printing technology “selective laser sintering (SLS)”. This process is characterized by exceptional attention to detail and precision.

What is selective laser sintering?

In selective laser sintering (SLS printing), a laser passes over polymer powder particles, fusing the particles together and building up the object layer by layer. The resulting, slightly rough surface is extremely detailed. As the laser sinteres layer by layer of the entire print space, SLS printing is particularly suitable for higher quantities and small series production, as well as detailed prototypes and end-user parts.

Our SLS printing capacities

Maximum size

159 x 159 x 295 mm (L x W x H)

Standard production time

2-3 working days

Dimensional accuracy

± 0.5% with a lower limit of ± 0.25mm

Layer thickness

110 µm

Upload your CAD files now and calculate your SLS print in real time!

Materials for SLS printing

PA12

High tensile strength and stability, low creep tendency. A high-quality, slightly rough surface.

Heat resistant up to approx. 170°CPA12GF (Only on request)

Extreme tensile strength and stability. Higher stiffness & heat resistance under load than normal PA12.

Heat resistant up to approx. 170°C

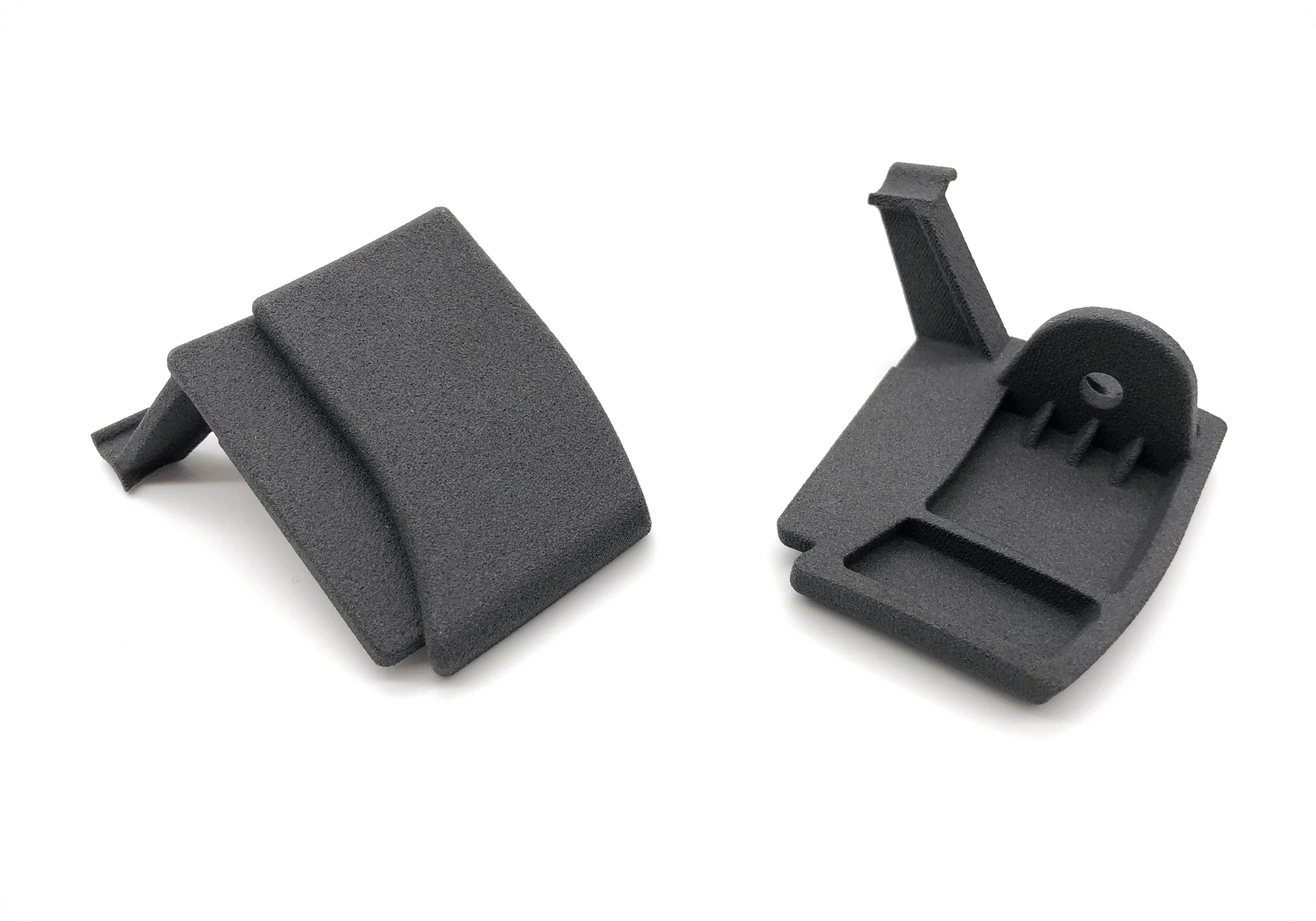

SLS-printed components of the highest quality

Due to the grey base material, you can obtain your SLS-printed components from us either in the original color or alternatively dyed black. The surface has a slightly rough powder texture with no visible layers.

References of our SLS printing quality