Fused Deposition Modeling

Get different prototypes and small series thanks to the enormous variety of materials of the 3D printing technology “Fused Deposition Modeling (FDM)”. As a standard process in 3D printing, FDM printing is the most widely used technology.

What is fused deposition modeling?

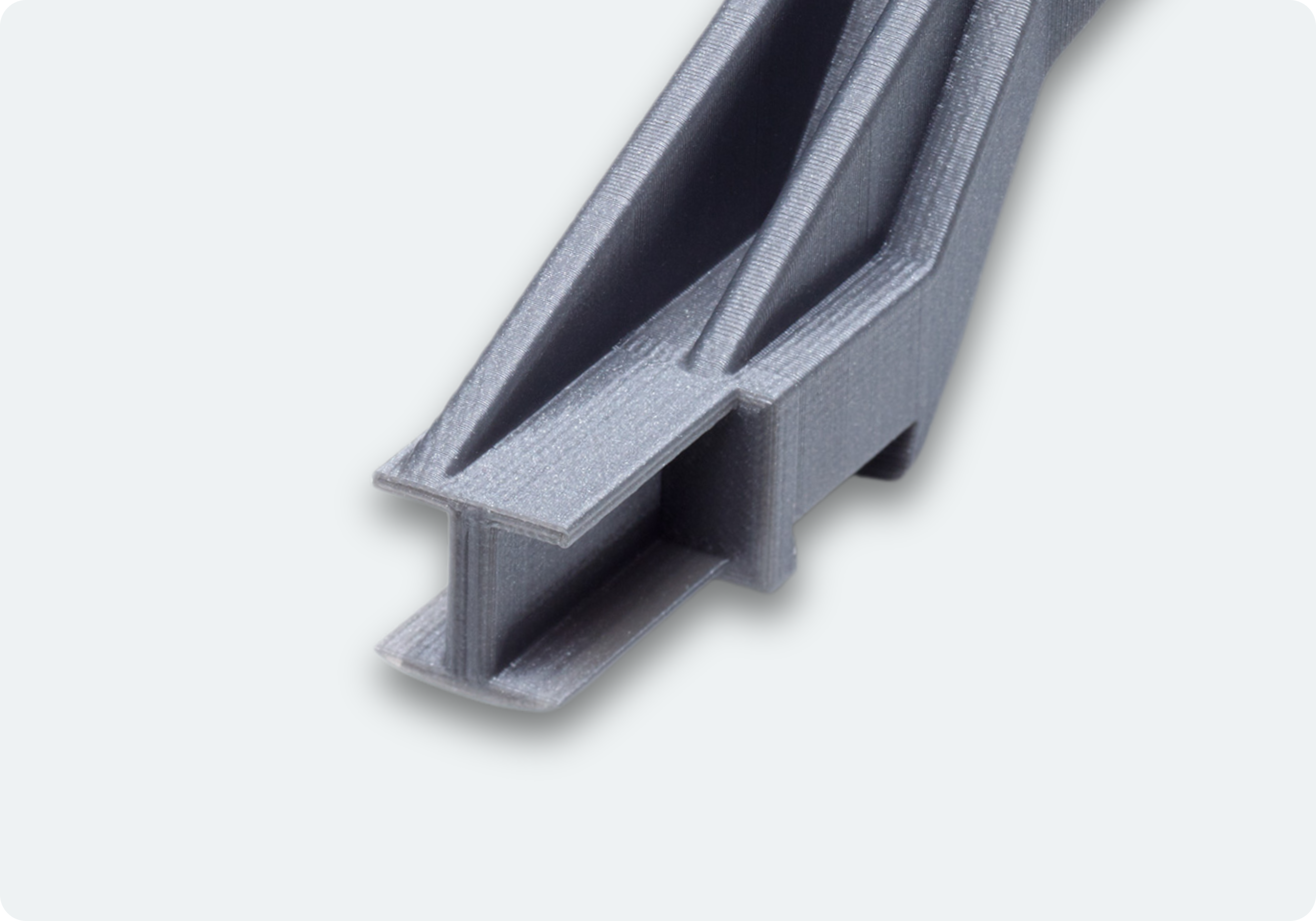

In fused deposition modeling (FDM), a plastic filament is heated, melted and applied in layers. This creates objects with the typical layered structure on the surface. The variety of materials and colors available for FDM printing makes this process more universal than SLS printing, for example.

Our FDM printing capacities

Maximum size

330 x 240 x 300 mm (L x W x H)

Standard production time

1-2 working days

Dimensional accuracy

± 0.5% with a lower limit of ± 0.25mm

Layer thickness

100 - 300 µm

Upload your CAD files now and calculate your FDM print in real time!

Materials for FDM printing

PLA

Good tensile strength and surface quality, high surface hardness, rigidity and tensile strength.

Heat resistant up to approx. 60°CT-PLA

Similar strength and higher rigidity compared to ABS.

PET

High toughness, chemical resistance and good wear resistance.

Nylon PA6/66

Impact and abrasion resistant, high strength-to-weight ratio, low coefficient of friction and good corrosion resistance.

Heat resistant up to approx. 85°CTPU 95A

High wear resistance, rubber-like flexibility, Shore A hardness 95, elongation at break up to 580%.

Heat resistant up to approx. 110°CPET-CF15

High heat resistance, strength and rigidity.

PAHT-CF15

High temperature and chemical resistance with excellent mechanical resistance.

Heat resistant up to approx. 110°C

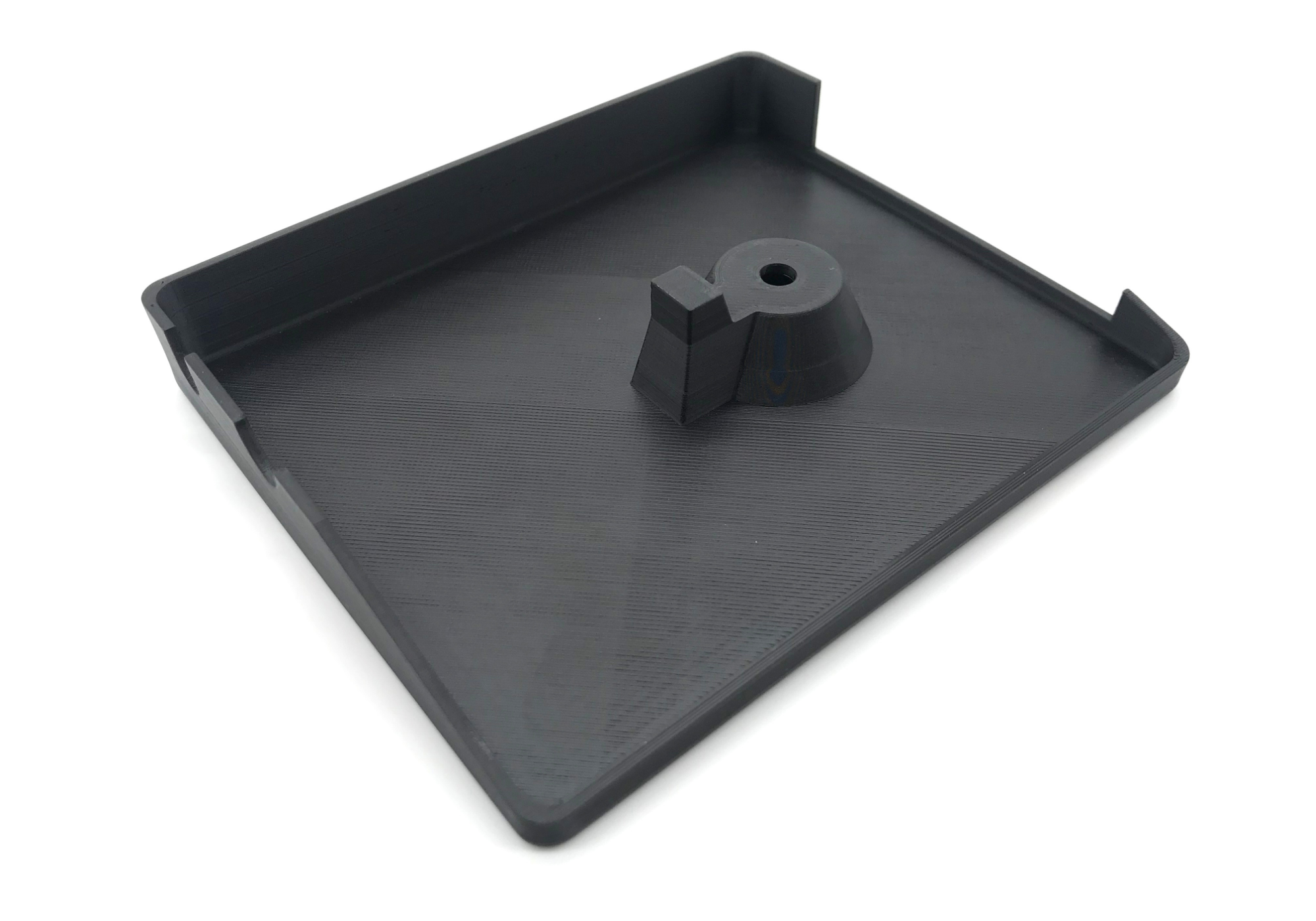

FDM-printed components of the highest quality

Individually post-processed, every FDM-printed component meets our high quality standards. This means you get components with high-quality surfaces and without defects or printing errors.

In other words: ready for the end user!

References of our FDM printing quality