Fused Deposition Modeling

Erhalten Sie unterschiedliche Prototypen und Kleinserien dank der enormen Materialvielfalt der 3D-Druck Technologie "Fused Deposition Modeling (FDM)". Als Standardverfahren im 3D-Druck, ist der FDM-Druck die am verbreitetsten genutzte Technologie.

Was ist Fused Deposition Modeling?

Beim Fused Deposition Modeling (FDM) wird ein Kunststoff-Filament erhitzt, geschmolzen und schichtweise aufgetragen. Daraus entstehen Objekte mit der typischen Schichtstruktur an der Oberfläche. Die Vielfalt an verfügbaren Materialien und Farben für den FDM-Druck macht dieses Verfahren universeller als beispielsweise den SLS-Druck.

Unsere FDM-Druck Kapazitäten

Maximale Baugröße

330 x 240 x 300 mm (L x B x H)

Standard-Herstellungszeit

1-2 Werktage

Maßgenauigkeit

± 0,5% bei einer Untergrenze von ± 0,25mm

Schichthöhe:

100 - 300 µm

Lade jetzt deine CAD-Dateien hoch und kalkuliere deinen FDM-Druck in Echtzeit!

Materialien für den FDM-Druck

PLA

Gute Zugfestigkeit und Oberflächenqualität, hohe Oberflächenhärte, Steifigkeit und Zugfestigkeit.

Temperaturformbeständig bis ca. 60°CT-PLA

Ähnliche Festigkeit und höhere Steifigkeit im Vergleich zu ABS.

PET

Hohe Zähigkeit, chemische Beständigkeit und gute Verschleißfestigkeit.

Nylon PA6/66

Schlag- und Abriebfest, hohes Stärke-Gewichtsverhältnis, geringer Reibungskoeffizient und gute Korrosionsbeständigkeit.

Temperaturformbeständig bis ca. 85°CTPU 95A

Hohe Verschleißfestigkeit, Gummiähnliche Flexibilität, Shore A-Härte 95, Bruchdehnung bis zu 580%.

Temperaturformbeständig bis ca. 110°CPET-CF15

Hohe Hitzebeständigkeit, Festigkeit und Steifigkeit.

PAHT-CF15

Hohe Temperatur- und Chemikalienbeständigkeit mit hervorragender mechanischer Widerstandsfähigkeit.

Temperaturformbeständig bis ca. 110°C

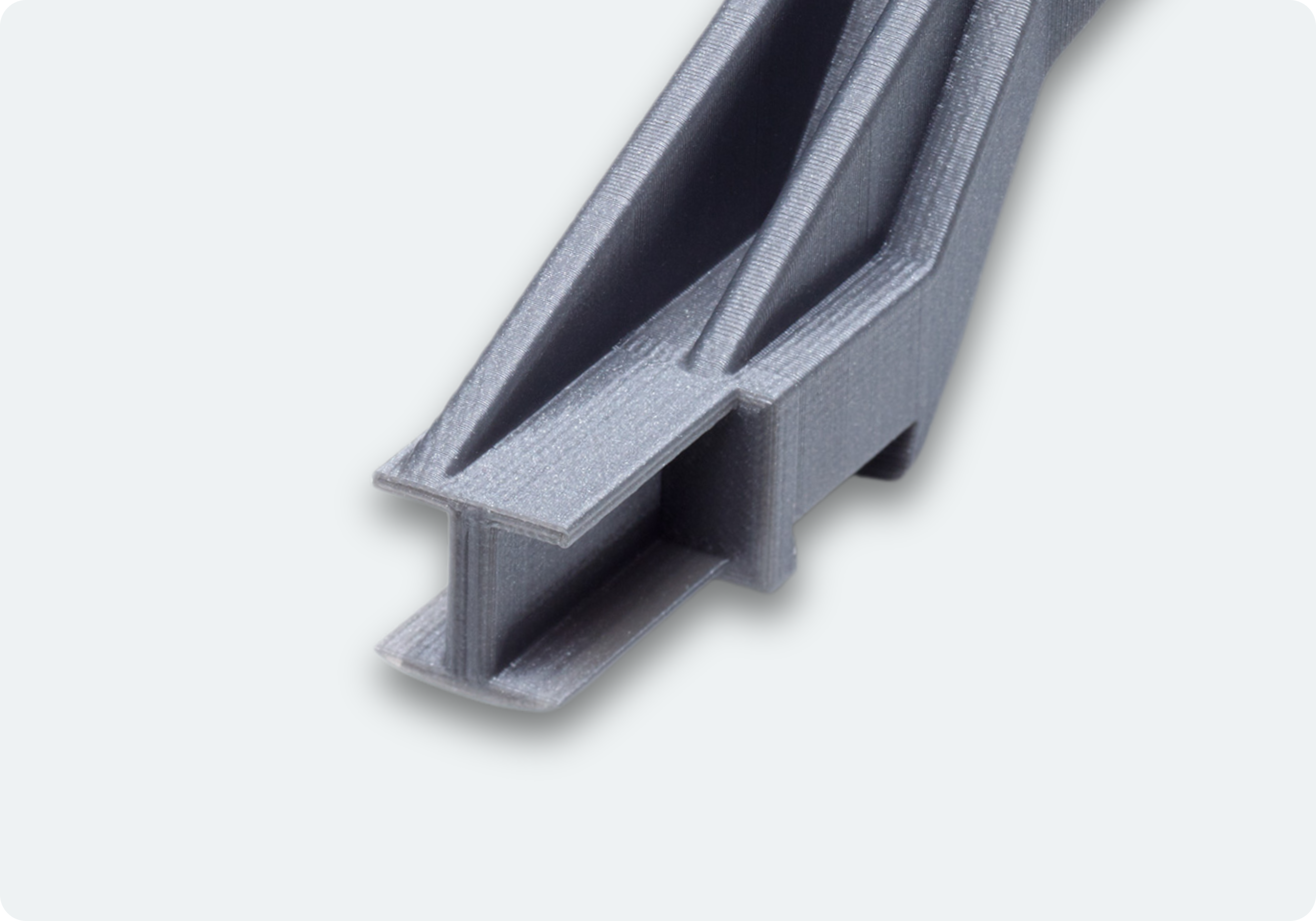

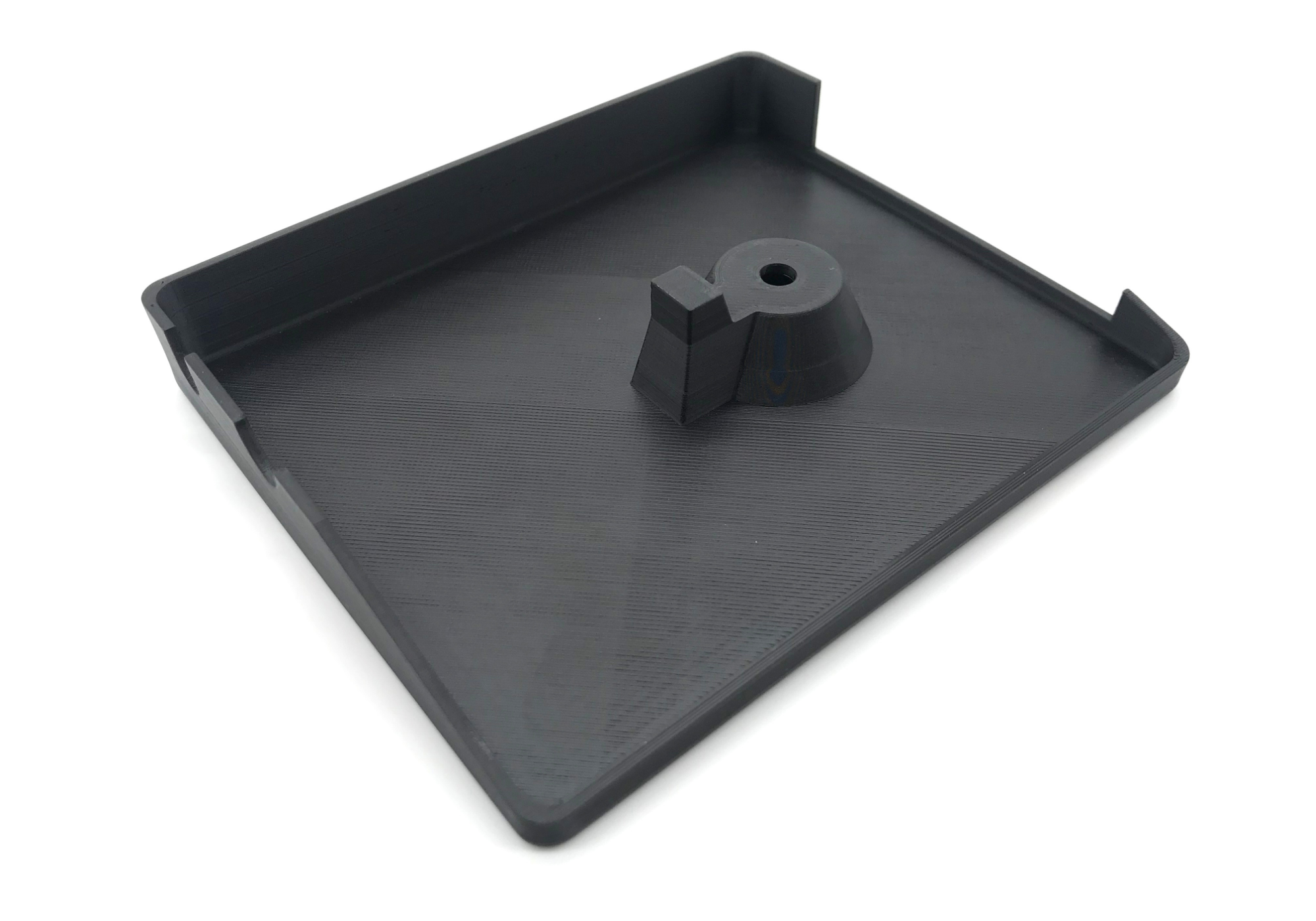

FDM-gedruckte Bauteile in höchster Qualität

Individuell nachbearbeitet erfüllt jedes FDM-gedruckte Bauteil bei uns hohe Qualitätsanforderungen. So bekommst du Bauteile mit hochwertigen Oberflächen und ohne Mängel oder Druckfehler.

Mit anderen Worten: Sofort Endverbraucher-fertig!

Referenzen unserer FDM-Druck Qualität